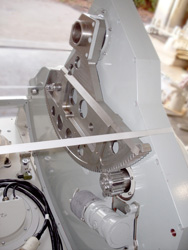

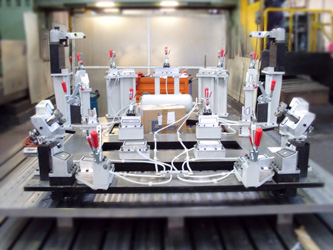

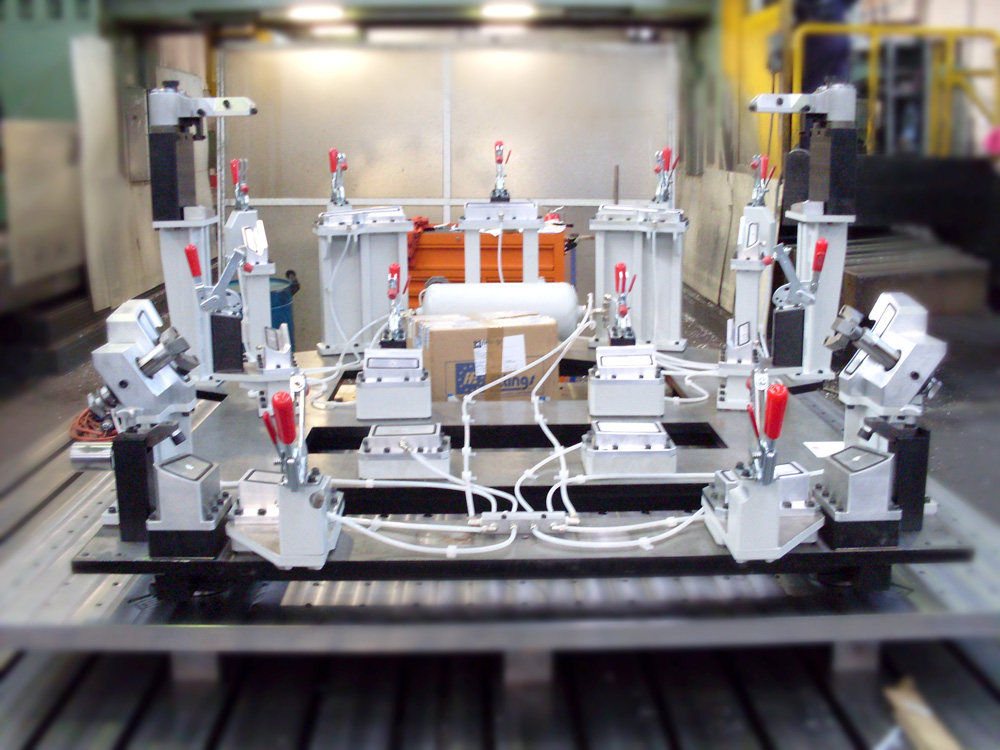

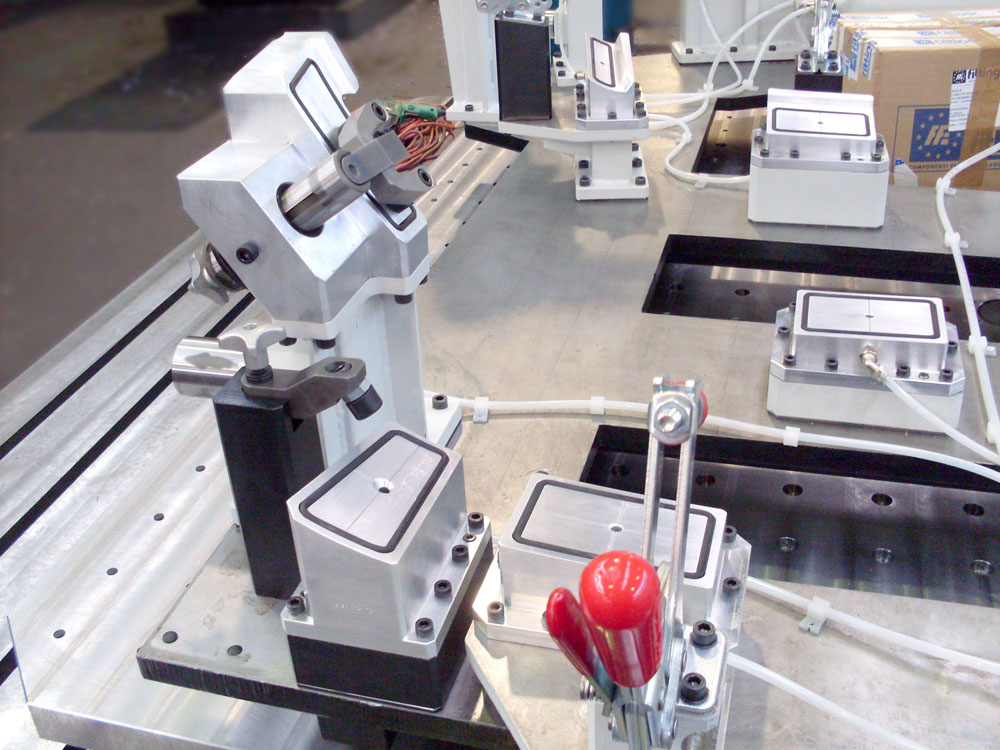

Mechanical components for assembly

BMD is capable of supplying mounted and tested assemblies and subassemblies

following the customer's

specificaions.

The assembly of these mechanical subsystems is done in an area of about

1000m2

adjacent to the internal design offices,

in order to have direct cooperation between the two departments in the case of construction of

assemblies

designed internally.

Testing of both components (dimensional inspection) and while assembly (functional testing) is performed internally with the tools present in the metrology room, including an anthropomorphic arm FARO and the FARO Laser interferometer. If the testing specs requires special tools or instrumentation, BMD can create those for a full specs compliance check.

The testing phases, such as production, follow strict quality standards which are dictated by the ISO 9001 quality management system ( certificate by DNV GL) and any specifications provided by the customer. BMD periodically performs part machining for avionics and defese, and is therefore able to provide all of the documentation requested by related quality specs.

Click on the photos to enlarge them