Shop-floor automation services

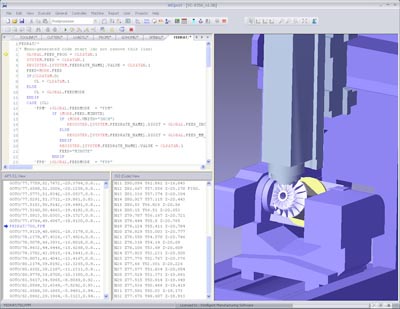

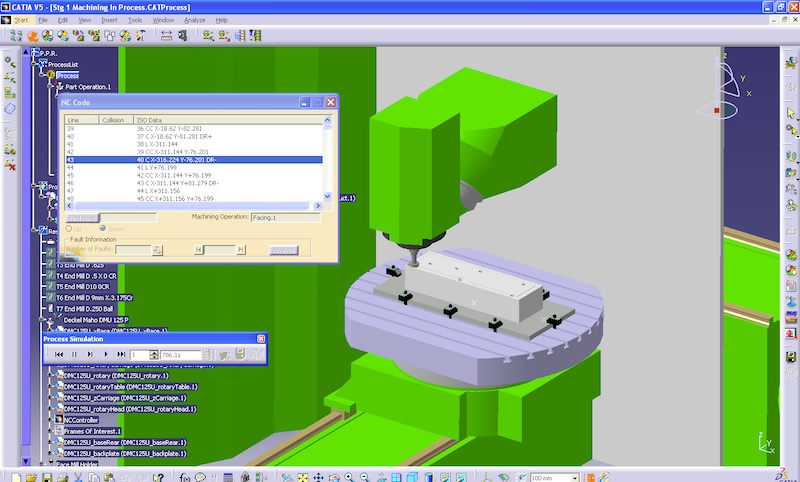

BMD has invested in software tools for machining simulation (CATIA V5 and PTC Creo CAM Packages) and for the generation custom NC-code (IMS-SOFTWARE's IMS POST). With these tools BMD can give support to customers whose need is manufacturing cycle development/simulation or the generation of specific NC-code for part machining.

BMD can also:

- provide custom post-processors through IMSPost, a tool that allows you to generate specific NC code

according to any customization of the milling / turning machine.

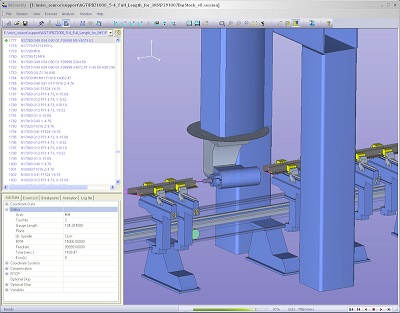

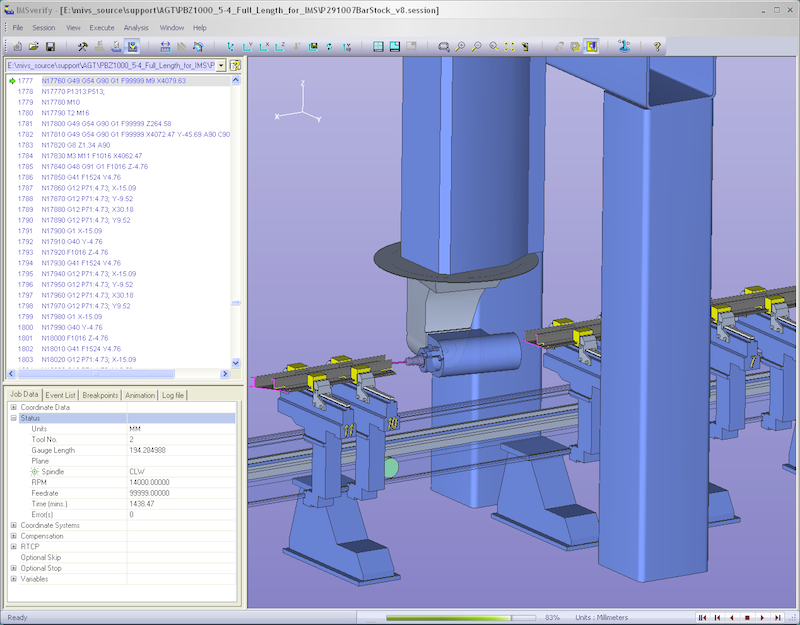

IMSPost interfaces with most CAM systems currently on the market, such as ADRA, AUTON, BihlerCAT, CADDS, CAMAX, CATIA / DELMIA (V4 / V5 / V6), CIMATRON, DELCAM, DUCT, Edgecam, EUCLID, Gibbs, Houtzel APT, I-DEAS, Intercim, INTERGRAPH, MASTERCAM, Metalcam, PTC Creo, SURFCAM, UNIGRAPHICS, VX, WORKNC and, based on a set of CNC controls and standard kinematics, allows you to provide custom output with support for high-speed milling, multi-axis machining, ARC Fitting of point-to-point paths in any plan, execution of 5 axes machining cycles. - Provide part program verification tools through IMSVerify, which allows to simulate the whole machining process starting from the generated NC code, thus making it possible to simulate the real chip removal, check the real movements of the machine on which the machining is going to be done, and to detect possible collisions and processing errors.

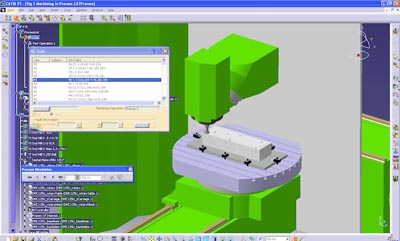

- Provide CE control emulators to use in the CATIA machine simulation environent, for testing of part programs generated within CATIA. This can be done with IMSCE, which integrates the same functionalities as IMSVerify inside CATIA.

Click on the photos to enlarge them